Updated: July 7, 2023

One of the distinguishing features of an innovative product is addressing the deficiencies of existing products and improving upon their known limitations and weaknesses.

Though homeowners have witnessed the advantages of composite decking and cladding over natural timber boards, they are just now realizing that not all composite board materials are of equal quality and durability.

Millboard’s product line of molded composite decking and cladding boards is an excellent example of understanding how one competitor, Millboard, can leapfrog the shortcomings of competing products. In Millboard’s case, molded composite boards are also proof that a superior man-made product can outperform nature, while also delivering beautiful, long-lasting aesthetic appeal via their patented molding process.

In this article, we explore Millboard’s unique approach to molded composite decking and cladding boards, while providing many reasons why homeowners should strongly consider this material for a wide-range of applications for exterior home projects and use.

Table of Contents

- Historic Problems with Natural Timber and First-Gen Composite Decking & Cladding

- Millboard’s Unique Approach

- The Benefits of Millboard Decking & Cladding

- Sample Decking and Siding Colors & Styles

- Creative Examples of Millboard Uses

- How Can I Purchase Millboard in the United States?

Also see:

- How to Create a Beautiful & Peaceful Outdoor Oasis

- Building Technologies for Disaster Resistant Homes

- Want a Tough House that Looks Great? Try Engineered Wood Siding!

- More Related Construction & Renovation Articles

- Related Topics: Sustainability | Construction | Indoor-Outdoor Living | Renovations | Maintenance

Historic Problems with Natural Timber and First-Gen Composite Decking & Cladding

The historic deficiencies of natural timber and first-generation composite decking and cladding can be grouped into the following issues:

- Mold and Fungus Growth

- Warping of Boards

- Fading and Finish Deterioration

Here are explanations of these documented shortcomings by material type:

Natural Timber

Natural, high-density timbers such as Cumaru, Garapa, Douglas Fir and Redwood, have long been the preferred material for most external cladding and wood decking projects. However, their recurring maintenance requirements and consumer sustainability concerns over natural forests have become deterrents for their continued use in recent years.

In addition to these issues, natural timber has several other disadvantages, such as:

- Wood-eating pests, such as termites

- Cracking

- Splintering

- Warping

- Fading, and

- Maintaining and the annual cost of ownership

Even many wood enthusiasts have conceded that natural timber is not the best economical choice for contemporary homeowners.

First-Generation Composite Decking & Cladding

Composite decking entered the scene in 1960, thanks to brothers Dino and Marco Terragni, who invented a polypropylene plastic composite that they patented called Covema. Wood fiber was later added to the plastic mix, to create WPC (wood-plastic composite).

Many years later in 1995, a division of Mobil-Oil Corporation gave rise to Trex, perhaps the first widely-known wood composite decking and cladding material known to modern homeowners.

Trex decking can still be found in homes across the United States as consumers were intrigued by the promise of “maintenance free” decking and cladding with the “look” of real wood.

However, a massive class action lawsuit in 2009 alleged that:

“the products sold by Trex were defective and susceptible to mold, mildew, fungus, or other spotting and discoloration. According to the Trex 25-year warranty, their decking products would not suffer from material defects or damage from fungal decay.”

Although Trex denied that the allegations had merit and insisted that the fungal damage that consumers witnessed were the result of environmental factors and not connected to their warranty, they still agreed to pay $8.25 million in damages to resolve the litigation.

Closeup view of fungal growth between two Trex decking boards.

Homeowners were subsequently left in a quandary, until other products began to enter the market that promised to improve on the areas where natural timber and Trex failed.

Millboard’s Unique Approach

Family-run, UK-based Millboard, has a history of marrying innovative British craftsmanship with improvements on nature’s weaknesses.

James Douglass, the founder of Millboard, had previous success with Stonemarket, a pioneer in composite “stone” slabs.

Stonemarket is known for its concrete paving slabs that mimic the look of stone but with improved performance features that natural stone does not provide.

Applying the same ingenuity that made Stonemarket a success, Douglass started Millboard. He recognized the inherent weaknesses of natural timber as well as the flaws of other composite decking materials that were available on the market.

Douglass succinctly understood that consumers wanted the beauty of natural wood, without the issues that accompany timber boards, such as warping, mold, termites and fading. He set out to produce a unique, proprietary material coated with a rubberized, proprietary, top-coating known as Lastane®.

This is perhaps the key factor in what makes Millboard’s products unusual as the Lastane® finish is non-porous and anti-fungal, unlike other composite products, and will provide a firm grip and non-slip surface. The result is a product that looks like real wood but performs better than natural materials and other composite board products.

Millboard’s Molding Process

Millboard decking is gaining favor with contractors and homeowners alike because the product provides the best of both worlds, specifically high-quality natural aesthetics and low-maintenance durability.

This is accomplished by their hand-molding process that captures and mimics the realistic grain, texture, and natural beauty of real timber for an authentic appearance of natural wood.

The boards are then hand-finished to a level that make fine grains standout, virtually indistinguishable from their natural counterparts.

Sample Decking and Siding Colors & Styles

The realistic quality of Millboard’s products can be experienced firsthand by requesting free samples (limit of 3) from the website of their sole US distributor Outlive. (Readers based outside of the US can request samples from Millboard’s UK website).

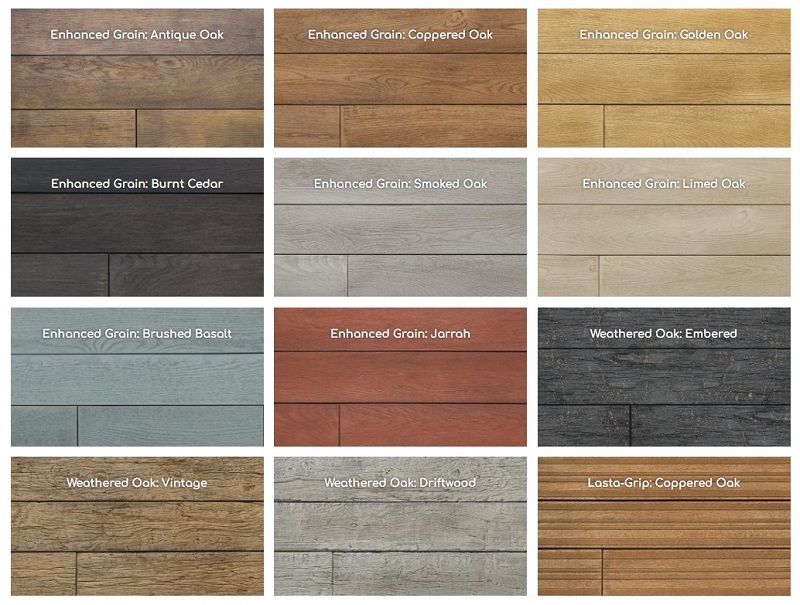

Decking comes in 3 finish styles (Enhanced Grain, Weathered Oak, and Lasta-Grip®) and 13 colors. (Note: Lasta-Grip® Golden Oak is not shown in the image below).

Sample decking colors and grain types

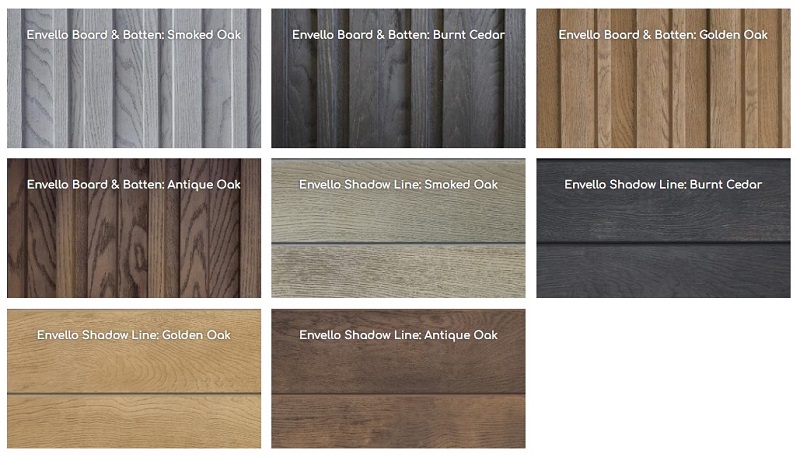

Sample siding colors, grain types and board styles

The Benefits of Millboard Decking & Cladding

Millboard’s focus on addressing the historic deficiencies of natural timber and first-generation composite materials resulted in their ability to deliver the following benefits:

- Real Wood Authenticity

- Sustainable Manufacturing Methods

- Strong but Lightweight Durable Material

- Slip-Resistant

- Low-Maintenance

- Multifunctional Uses

The result of this beneficial combination is an ideal decking and cladding product that has the following impressive traits:

- Will not warp due to the rubberized but rigid polyurethane

- Is strong due to mineralized limestone and fiberglass

- Is extremely lightweight

- Is rot and split resistant

- Is sliver free

- Will not host insect larvae or mold spores in damp environments, due to not having wood fiber or wood content

- Is sustainable by not requiring wood content and being long-lasting

- Is easy-to-maintain, as it washes clean simply and safely with soap and water

- Is installed with hidden fasteners which helps to maintain a seamless “real timber” appeal with no exposed screws

The lack of wood fiber makes it perfect for decking and cladding in termite-prone areas that thrive in warm climates with ample moisture for their survival and proliferation.

The Lastane® coating means you will never need to stain or oil another deck for the life of your Millboard product, as it will still have a factory-finish aesthetic, backed by their 25-year warranty.

How to Maintain Millboard Decking

Creative Examples of Millboard Uses

Millboard molded decking was brought into the market predominantly as an outdoor flooring product since its development in 2007. (Millboard the company was established in 1976). However, the durability, ease of maintenance, versatility and natural timber beauty has extended its use well beyond flooring.

Millboard products have inspired landscapers, gardeners, architects, homeowners, builders, and crafts enthusiasts to apply the innovative material to a wide-range of creative applications, such as:

These wide-ranging applications and impressive traits make Millboard a “must-have” component of any outdoor oasis.

Also see:

All images are courtesy of Millboard and Outlive.

Decks

Siding

Permanent Outdoor Seating

Outlive’s showroom with examples of permanent outdoor seating

Pathways

Living Walls

Pool Decks

How Can I Purchase Millboard in the United States?

In the United States, Millboard molded composite decking and cladding can only be purchased through its sole distributor, Outlive, headquartered near St. Paul, Minnesota. As an authorized distributor of Millboard products, Outlive continues the legacy of molding, fabricating and finishing of Millboard’s high-quality cladding and decking boards across the pond in their own US-based facility.

- Link to request free samples (limit of 3)

Related Construction & Renovation Articles

- Best Roof Types to Prevent Storm Damage

- 7 Tips on How to Make Your Home Up-to-Date & On-Trend

- 7 New Innovations in New Home Building

- Luxury Vinyl Plank Flooring: Friend or Faux?

- 5 Examples of Older Homes Returning Maximum Profit with Renovations

- What is a Turnkey Home in Today’s Market?

- Need Renovation Inspiration? Try These Innovative Design Resources!

| Purgula is reader-supported. When you click on links to other sites from our website, we may earn affiliate commissions, at no cost to you. If you find our content to be helpful, this is an easy way for you to support our mission. Thanks! Learn more. |