With the exploding popularity of LVP, Luxury Vinyl Plank flooring, here’s what you need to know to be sure that it’s a good fit for your project and home.

We have toured many open homes recently, especially newly renovated or “flipped” properties, looking for new design, materials and technology trends.

One common theme that we have begun to notice is the explosion of installations using Luxury Vinyl Plank (LVP) flooring that is engineered to resemble wood, but is relatively inexpensive and easy to install.

Having encountered one very disappointing implementation of LVP, this peaked our curiosity to investigate:

- Should you consider this new flooring innovation in your home?

Table of Contents

- What is LVP (Luxury Vinyl Plank)?

- Pros & Cons of LVP

- LVP vs. Water Resistant Laminate

- LVP vs. Hardwood Flooring

- Plank Glue or Floating Installation?

- LVP Flooring: Is it Right for Your Situation?

- Most Popular Brands of Luxury Vinyl Plank Flooring

Also see:

- The Latest in Residential Floor Restoration Solutions & Options

- A Before vs Virtual vs Real Life Renovation Case Study

- 5 Examples of Older Homes Returning Maximum Profit with Renovations

- How to Sell Your Home for Maximum Profit with Revive

- What is a Turnkey Home in Today’s Market?

- Additional Recommended Reading

What is LVP (Luxury Vinyl Plank)?

Luxury Vinyl Plank, known simply as LVP, is a thick flooring material that is sold in planks, or long, narrow strips, with a modified tongue-and-groove or click-lock system that can be snapped together.

The finished product is a combination of synthetic materials that are formed when combining Polyvinyl Chloride Resins (PVC), pigments, calcium carbonate, plasticizers, fungicide, print film, and Ultra Violet (UV) stabilizers.

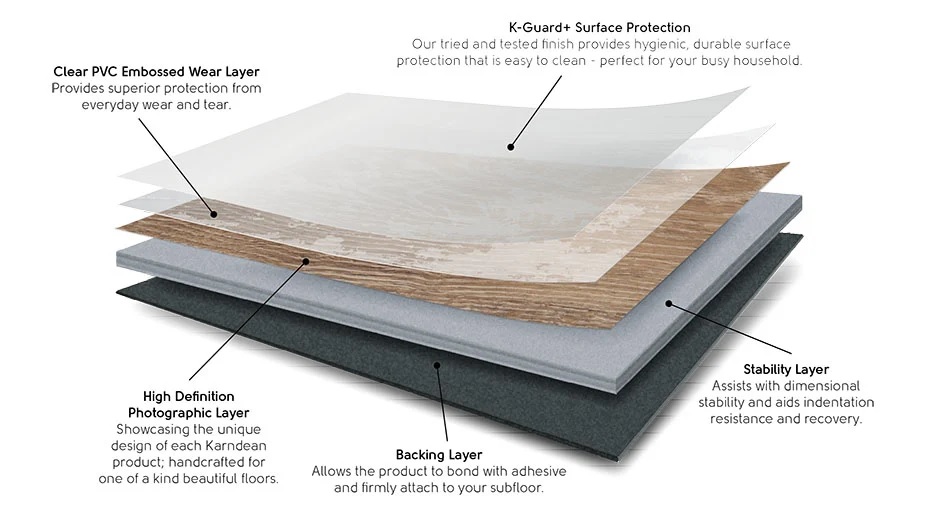

4 Layers of Composition

A vinyl plank has four layers of composition, with each layer providing a characteristic to create the overall “luxury” quality:

- Wear Layer

- Decorative Layer

- Flexibility Layer

- Backing Layer

Diagram courtesy of Karndean

Wear Layer

The top or “Wear” layer is comprised of aluminum oxide to prevent fading, scratches, scuffs and other signs of everyday wear, while providing easy maintenance.

The thickness of a product refers to this layer, measured in millimeters or “mil’ or “mm”. The higher the mm, the more durable the product is, as it protects the plank from everyday use. Some products have an additional coat on top of the “wear layer” for extra protection or sheen (AKA “top coat”).

Decorative Layer

The second or “Decorative” layer provides the desired appearance of the floor, such as stone or wood. This is achieved by adhering a thin digital image or print film to the vinyl core of the plank, which gives the product its color and pattern.

Flexibility Layer

The third or “Flexibility” layer is the waterproof vinyl core, comprised mainly of PVC, for stability.

Backing Layer

The fourth or “Backing” layer allows the plank to bond to the adhesive and attach firmly to the subfloor.

Pros & Cons of LVP

Although our empirical sampling of new home renovations tells us that LVP is extremely popular with builders, real estate professionals and DIYers, we wanted to understand the pros and cons of this product, to learn how we might want to use it in our own household.

Pros of LVP

Ease of Maintenance

Always number one on our list for products is the amount of effort required to maintain a product’s original look. We are not fans of endless upkeep that may be necessary for some luxury products, even if they lend an elegant enhancement to our décor.

Fortunately, all manufactures of LVP contend that their products are easy to maintain and this sentiment is backed by actual customers in chat rooms and other flooring support sites.

Ease of Installation

The overall assessment from DIYers is that LVP is fairly forgiving and easy to install. However, LVP is locked in place with the “tongue and groove” system of installation, some installers lament that this system can become arduous, when planks get stuck while clicking them in place.

Importantly, the planks need to be installed over a perfectly flat subfloor – no crowning or sagging joists – which might require sanding of high spots and filling of low spots. DIYers tend to agree that as long as the subfloor is perfectly prepped, LVP is as easy as installing LEGO blocks.

Waterproof

LVP manufacturers claim their products are waterproof, which means that water will not damage them or cause them to swell from moisture. In other words, moisture can penetrate at the seams, but the “waterproof” ratings means that the floor will not warp or buckle if exposed to moisture.

Cons of LVP

- Damaged Planks Are Difficult to Repair

- Less Prestigious than Hardwood (Lower Resale Value)

- Click-Lock Joints May Be Difficult to Connect

- Steam Cleaning Can Damage the Subfloor

- Flooring Can Sound Squeaky or Feel Bouncy

- Moisture Can Be Trapped Under Non-Breathable Vinyl

Damaged Planks Are Difficult to Repair

Perhaps the most common complaint from consumers is that repairs with LVP can be difficult. Although a small area of damage can be repaired with a patching kit, larger areas, such as the removal of an entire plank, require that the floor be disassembled from one wall up to the damaged plank. Once the plank is replaced, the reassembly back to the wall must be performed.

Less Prestigious than Hardwood (Lower Resale Value)

Depending on the look you wish to achieve, LVP will never return the same look as natural hardwood flooring or stone. There are a variety of manufactures and designs from which to choose. However, if you want the authentic look of natural stone, porcelain or wood, you will not find it in LVP.

Click-Lock Joints May Be Difficult to Connect

As mentioned previously, the number one issue that plagues DIYers is the clicking of the blocs to achieve that “Lego” effect of joining the planks together. Although the LVP kit comes with a tapping block, many veterans of the floor trade have offered alternative methods of overcoming this problem and it appears it takes a little bit of luck and skill to perfect the attachments.

Steam Cleaning Can Damage the Subfloor

While the LVP flooring itself is impervious to moisture, the pressure of a steam cleaner can potentially drive moisture down through the seams to the wooden subfloor and create issues such as mold, mildew or wood rot.

Flooring Can Sound Squeaky or Feel Bouncy

All manufacturers require that installation begin with a completely level subfloor or concrete slab. Most manufacturers call for the subfloor to be within 3/16″ over a 10 foot radius, meaning before laying LVP the subfloor must be extremely flat.

Should you lay planks over dips, dimples or other subflooring imperfections, the result may be squeaky or bouncy flooring that may eventually become damaged or begin to shift.

There is, however, a fix to this problem: always install planks that are 7mm or greater in order to provide ample thickness, as they are more forgiving of subfloor or concrete slab imperfections than thinner 4mm planks.

We recently visited a renovated home listed for sale that had squeaky, bouncy floors throughout the home, which could be a deal killer, in our opinion.

Moisture Can Be Trapped Under Non-Breathable Vinyl

Some home contractors have recounted that although LVP can be water resistant, moisture can become trapped underneath the vinyl, creating a pool of mold that is a hazardous and pungent situation when pulling up planks.

LVP vs. Water Resistant Laminate

We compared LVP to Water Resistant Laminate in six categories most important to homeowners:

- Pricing

- Thickness

- Water Resistance

- Installation

- Durability

- Aesthetics

Pricing

Although laminate is much less expensive, there are varying price points for LVP products depending on the quality, durability and warranty. Requesting add-on features and aesthetic traits can push the pricing towards the cost of a natural material.

Thickness

LVP is measured in millimeters (either “mil” or” mm”), which is a measurement of the wear layer. Depending on the application or intended use, LVP products are available from 4mm to 20mm with the latter being commercial grade or the most durable of the spectrum.

Water Resistance

Laminate flooring is water resistant not waterproof. There is a very big difference in these terms. Water resistant flooring products are not guaranteed against standing water and can therefore bubble or warp, even though some products have a 72-hour- standing-water-guarantee.

Water may leak through seams and into the subfloor, creating mold, mildew or other issues. LVP is waterproof and can be reused after water damage once it has completely dried. Many LVP products are guaranteed against mold or mildew, are hypoallergenic and do not absorb odors.

Installation

Laminate flooring requires underlayment plastic or padding before the laminate can be installed onto the surface and requires sealers after installation. LVP installation requires a perfectly level subfloor or concrete slab and may require some trial and error on learning the trick to interlocking “tongue and groove” placement.

Durability

Laminates have been known to scratch easily, and are not recommended for homes with indoor pets. LVP products are available at different wear levels and should be chosen based on specific situations, such as traffic levels and traffic type (e.g. kids, pets, shoes-off vs. shoes-on household, etc.).

Aesthetics

Although laminates have more of a wood feel, many customers lament that after a year or so they do not hold their aesthetic value. LVP products look expensive and hold their aesthetic appeal over longer period of time, although the plastic resins in them cause them to have a “strange feeling” to bare feet.

LVP vs. Hardwood Flooring

We also compared LVP to natural hardwood in six categories most important to homeowners:

- Pricing

- Thickness

- Water Resistance

- Installation

- Durability

- Aesthetics

Pricing

Although raw material costs in some areas are not necessarily different, the cost of installation of hardwood is higher than that of LVP flooring. With various price points and varying thickness, LVP products can be less expensive than natural hardwoods, which likely explain their popularity.

Natural wood flooring is roughly 5 to 10 times more expensive than the lowest cost LVP products. Many consumers of LVP flooring tout that its inexpensive pricing allows you to change your mind and choose another design, if you become tired of your choice after 5 years.

Thickness

LVP products come in varying thickness and it is important to choose the appropriate thickness for your needs. Similarly, natural wood planks, depending on the type – e.g. Oak, Ash, or Bamboo – are available in varying thickness.

Water Resistance

LVP flooring is waterproof and better for homes with a high probability of accidental water issues, such as pets, children and flooding. Hardwood’s natural enemy is water.

Installation

Cost of installation for hardwood is more expensive than LPV products, with the latter being easy enough for homeowners to DIY and save on installation costs.

Durability

LVP takes a beating, but depending on the wear rating of thickness, will hold up to many of today’s toughest everyday abuse. Depending on the type of hardwood used in flooring, you may need to perform upkeep, especially against pet accidents and other water related mishaps.

Many consumers believe LVP gives them peace of mind against scratches and other damage that hardwood is prone to in everyday living situations. Hardwood floors have durability, especially in older homes, and are good for strong resale value. LVP may last twenty years, but will it look as good?

Aesthetics

For higher-end homes, there is no substitute for natural hardwoods and stone, as buyers expect luxury, high-quality, natural materials. Hardwood flooring is not susceptible to separation at the seams unlike some LVP flooring. Scratches on laminates require replacement, while hardwood can be repaired with buffing and coating to restore its original appearance.

Plank Glue or Floating Installation?

LVP products can either be glued to the subfloor or allowed to float on top of the subfloor, without adhesive. Whether you decide to glue or float depends on your particular preference or situation, but we offer some reasons and situations as to why you would choose one over the other.

Glue LVP Installation Method

Proponents of the glue down method state that the adhesive, or glue, allows the planks to remain intact and in place for years. The floor feels more sturdy and durable, with less movement underfoot, as the planks are affixed to the floor and do not peel away.

Gluing the planks to the subfloor also has a repair advantage in that individual planks can be repair by pulling up the damaged plank and replacing next to an undamaged neighbor without touching the neighboring plank.

The disadvantage of gluing LPV flooring is that it takes considerable more time to install and involves working with adhesives which can become messy and more labor intensive. The leveling of the floor for a glue installation is extremely important as an imbalance due to dimples or dips in the subfloor can make the installation problematic.

Best Rooms for Glued LPV

Larger spaces, such as great rooms, and high traffic areas that will need to withstand constant wear and tear and movement are strong candidates for the glue installation method.

Armstrong Rigid Core Vantage A6950 LVP Living Room Flooring

Floating LVP Installation Method

Floating LVP flooring sits atop the subfloor or concrete slab without being affixed to the base. Their anchoring is the result of the click-and-lock system that maintains the planks, similar to a jigsaw puzzle’s pieces. Installation is much easier for floating flooring and the imperfections of less-than-perfect subflooring are more forgiving.

The biggest challenge, of course, is that like a jigsaw puzzle, one damaged piece requires that an entire section, up to the nearest wall, be removed in order to make a replacement.

Best Rooms for Floating LPV

Floating floor are best for smaller spaces, narrow hallways and rooms prone to moisture – such as a basement, laundry room, kitchen, or bathroom – since the floating planks are not adhered to the subfloor, they are less likely to suffer moisture damage.

LVP Flooring: Is it Right for Your Situation?

LVP flooring is clearly very popular today and is truly a personal aesthetic choice. Any installation in a home should take resale value into consideration, especially if you plan to live in the newly re-floored home longer than 10 years.

For our household, we would only consider LVP products for smaller, more personal rooms, such as a laundry or home office, but not for a great room, kitchen, bathroom or master suite.

Mannington Adura Rigid Dent Resistant LVP Flooring

We are partial to natural hardwoods and stone, as we are a “shoeless household”, and our guests have come to expect to remove their footwear this when they enter our home. The feel of natural products under our feet is something to which we have grown accustomed and the strength of the woods and stone feel solid and luxurious to our bare or sock-covered feet.

However, some manufacturers of luxury plank flooring do offer embossed or registered textures that provide a similar wood-like feel. Some also offer LVP with ceramic beading to provide extra durability and traction against slips or slickness susceptible with standard vinyl.

Here are our recommended residential “use-cases” for LVP:

- People wanting a wood aesthetic in the kitchen, bathroom, or other water-prone areas of the house

- Rental properties

- High traffic areas

- Less prominent areas of the home: e.g. converted garages, attics, workrooms, etc.

Our key takeaways when choosing flooring for your home or an investment property are the following:

- Do your homework to understand the traits of the flooring material that best match the likely usage of an area over several years

- Identify the best installation method for the given type of material and intended usage

- Try to sample as many “real life” installations to get familiar with the combined aesthetics, feel and durability of a flooring type, so that it best meets your long-term expectations

Most Popular Brands of Luxury Vinyl Plank Flooring

Most Popular Brands for Luxury Vinyl Plank Underlayment

Recommended Reading

- A Before vs Virtual vs Real Life Renovation Case Study

- 5 Examples of Older Homes Returning Maximum Profit with Renovations

- How to Sell Your Home for Maximum Profit with Revive

- What is a Turnkey Home in Today’s Market?

- Need Renovation Inspiration? Try These Innovative Design Resources!

| Purgula is reader-supported. When you click on links to other sites from our website, we may earn affiliate commissions, at no cost to you. If you find our content to be helpful, this is an easy way for you to support our mission. Thanks! Learn more. |

n>