How the latest advances and offerings from leading engineered wood siding brands compare to traditional options of aluminum, vinyl, fiber cement and natural wood.

Wood, aluminum, fiber cement and vinyl siding were all very common in the Northeastern part of America, where we spent the first half of our lives. Beautiful homes with perfect wood, aluminum, cement or vinyl sided to Colonial, Ranch and Saltbox architectures – some with their matching barns or detached garages were visible from the road, as we drove up I-95 during the summers of our youth.

A recent visit back east, after having lived in California for a good portion of our adult lives, caused us to wonder:

How much upkeep is involved in maintaining older siding materials?

What are the advantages and disadvantages of newer innovations, such as Engineered Wood Siding (EWS) over more common Aluminum, Vinyl, Fiber Cement and Wood siding? Here’s what we learned.

Table of Contents

- Innovations in Engineered Wood Siding

- How Engineered Wood Siding is Manufactured

- Advantages and Disadvantages of EWS

- Comparison of Home Siding Types

- Leading Manufacturers of Engineered Wood Siding

- Visual Design Tools & Galleries

Also see:

Innovations in Engineered Wood Siding

There is no question that natural wood siding made of Cedar or Redwood trees is absolutely beautiful and extremely natural-looking with an unmatched aesthetic. However, the biodegradability of the 100% natural material can be costly over time and can be prone to termites, mold, mildew, warping and other damage brought on by extreme weather conditions. Factor in the amount of upkeep each year, and it can become a very costly and time consuming proposition.

Engineered wood siding is unique in that it is equipped to handle situations where other siding types fail, thanks to the treatments included in its construction. Owing to its origins of being derived from wood particles, EWS is considered a natural product, unlike vinyl or aluminum, and can be used to replace other natural products namely wood or fiber cement.

LP SmartSide: Is Your Siding Tough Enough?

How Engineered Wood Siding is Manufactured

Engineered Wood Siding (EWS) is an alternative product to real wood siding, as it uses thin strips of leftover natural wood and fibers that have been pressure treated, pressed together and bonded using a resin to create a stronger product. The result is a siding product that has the appearance of wood, yet is resistant to many of the enemies of natural wood, such as termites, mold, mildew, dry rot, and weather damage, such as hail.

Engineer Wood Siding has the appearance of wood, yet is resistant to many of the enemies of natural wood

After bonding of the wood and fiber strands, the pressurized result is then heated to further increase strength and durability. A wax coating is then applied to help increase the engineered wood siding’s resistance and impermeability to moisture, mold and mildew.

The final step involves treating the EWS with zinc borate to improve its resistance to fungal rot and other pest infestations. The product is then cut into planks, shakes, panels, window trim or a variety of shapes as needed.

Advantages and Disadvantages of Engineered Wood Siding

A similar product, Composite Wood Siding, was the predecessor of EWS during the period of 1980 to the mid-1990s. The composite wood product failed miserably and was the target of class-action lawsuits when moisture entered the product and caused premature material failure. Manufacturing and construction defects caused the wood to crumble, crack, rot, and in some instances, buckle.

Although the last settlements were issued around the end of December 2002, homes built and sided with these products still exist, as their owners still continue to seek resolution and compensation.

The difference in today’s engineered wood products, compared to the first-generation of composite siding, is in the use of wood strands instead of wood fibers. Engineered wood uses treated wood strands combined with a resin binder for strength. Composite wood siding uses weaker, cellulose fibrous wood pieces that are bonded with additional materials. Engineered wood is more flexible making it less prone to breakage, while also requiring less maintenance than its composite wood counterpart.

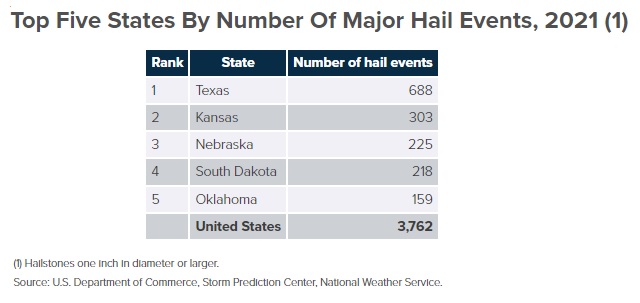

Hail-related insured losses between 2000 and 2019 averaged between $8 billion to $14 billion a year, according to Aon.

During tests conducted at the National Wind Institute’s Debris Impact Facility at Texas Tech University, engineered wood siding showed no signs of impact after being struck by 1.75-inch hail at 81 miles per hour – excerpt from Understanding the Durability Attributes of Engineered Wood Siding

Image courtesy of the Insurance Information Institute

Although EWS has distinct and overwhelming advantages over other siding materials, including composite wood siding, we suggest purchasing EWS products from top brands that warranty their products against any future defects, or unforeseen circumstances due to material failure. Better manufacturer warranties cover many concerns against fading color, cracking or other material defects with generous multiyear coverage.

Although engineered wood siding has been on the market since the late 1990’s, competitive product manufacturers of vinyl and aluminum siding still claim that it is a new product. One of the earliest EWS products, has been on the market for over 20 years and is still one of the fastest-growing EWS brands in the nation today.

Advantages of Engineered Wood Siding

- Easy & inexpensive to install

- Easy to cut and work with, using existing woodworking skills and tools

- Durable

- Low maintenance

- Doesn’t warp

- Available in a wide selection of aesthetic options: colors, textures, and finishes

- A less-costly alternative to real wood

- Is a better aesthetic choice to mimic the look of traditional wood siding, than vinyl or fiber cement siding

- Doesn’t peel or chip easily

- Sustainable as it is made from recyclable materials

- Only requires repainting every 10 years or so

- Long lifespan of 20 to 30 years

- Long-term warranties available

- Homes can be covered in fewer pieces than other materials

- High resistance to:

- Water damage

- Weather damage, including hail

- Fungus

- Pests

- Mold and mildew

- Wide temperature fluctuations

Colorful closeup view of fish scale engineered wood siding by TruWood.

Disadvantages of Engineered Wood Siding

- The finish can look unnatural and lacks the natural variations found in real wood

- Full lifespan is uncertain, as it is still a relatively new product

- Resin coating may crack over time

- Any cracks or damage to the product can allow moisture to seep in

- Colors can fade over time

- Binding agents used to create EWS are not eco-friendly

- Dioxins, a known carcinogen, are released during the manufacturing process of EWS

Comparison of Siding Types

We compared Engineered Wood Siding against the most popular siding materials on the market today: Wood, Vinyl, Fiber Cement and Aluminum. We used categories that are most important to homeowners namely: cost, durability, aesthetics, installation ease and of course manufacturer warranties.

| Cost Per SQ. FT. Installed | Maintenance | Durability | Aesthetics | Installation Ease | Average Lifespan | |

| Wood | $10.50 – $17.50 | Requires routine & annual maintenance | Durable if maintained | Natural beauty | Easiest to install | 15 to 40 yrs |

| Vinyl | $7.50 – $15.50 | Low maintenance | Strong UV Rays or High Heat can cause melting | Poor aesthetics; Plastic-like | Easy to install | 50 yrs |

| Fiber Cement | $10.50 – $17.50 | Moderate maintenance | Durable, long lasting | Improved technology better aesthetics | Very labor-intensive process | 25 to 40 yrs |

| Aluminum | $3.00 – $7.25 | Painted siding requires repainting every 5 to 10 years | Prone to denting, scratching & fading | Poor aesthetics | Expensive to install | 30 to 50 yrs |

| Engineered Wood | $10.50 – $16.50 | Lower maintenance than natural wood | Durable & resistant to wood enemies | Closely approximates natural wood | Easy to install | 20 to 30+ yrs |

Leading Manufacturers of Engineered Wood Siding

As previously suggested, only purchase products from manufacturers who stand behind their products with generous warranties against manufacturing defects or unforeseen product breakdown. We have listed the top EWS producers that have come recommended by general contractors, together with links to their product warranty information.

AZEK

AZEK siding is known for being the most maintenance-free of the EWS products, as it has an engineered polymer technology that is resistant to inclement weather. Known for its proprietary PaintPro® Technology, AZEK EWS allows paint to glide on with better efficiency and adhesion. Additionally, AZEK siding is made from a state-of-the-art proprietary engineered polymer that does not absorb water like porous materials and is completely rot-resistant inside and out. The company offers a Lifetime Warranty on all of its EWS products.

AZEK Vertical Siding

Accoya

Accoya is the brand name for the engineered wood siding product also known generically as acetylated wood. Manufactured by Accsys Technologies, a UK-headquartered parent company, which specializes in combining chemistry, technology and ingenuity to achieve high performance sustainable wood products. Approved by leading independent European timber research associations, Accoya has proven to be as durable as timber. With the backing of both BRE (British Research Establishment) and TRADA (The Timber Research and Development Association), Accoya has an unrivaled 50-year product warranty for above ground constructions.

Accoya Acetylated Siding

KWP

KWP is a 40+ year-old eco-conscious manufacturer of building materials headquartered in Quebec, Canada. As a leading producer of quality engineered wood siding and trim, KWP continues to design and innovate across its various product lines to keep pace with both the industry and the ever changing environment. KWP offers a 50-year warranty to its customers, which includes protection against denting, cracking and hail damage. It also offers a 25-year warranty on the finish.

KWP Engineered Wood Shake Siding

LP SmartSide

Louisiana Pacific Corporation rebranded themselves as LP after the debacle with an older siding product, Inner Seal, which resulted in the largest siding class action lawsuit in US history at $500 million. Contrite and retooled, LP introduced LP SmartSide after reverse engineering the problems that led to the Inner Seal problems.

The History of LP SmartSide After 20 Years of Success

A rigidly tested and reformulated product that has fulfilled the company’s promises of bringing a better solution to market, LP SmartSide is the fastest growing Engineered Wood Siding product on the market today.

LP’s confidence in its products is backed by a 50-year prorated Limited Warranty that includes a five-year, 100% labor and material replacement feature. Hail damage is also included in the warranty.

LP SmartSide Blue Front Porch

TruWood

TruWood is manufactured by Collins Products, a family owned business since 1855, and currently has a very healthy share of the engineered wood siding market. Based in Klamath Falls, Oregon, the company has earned a well-deserved reputation for unparalleled commitment to customers and standing behind its products. The company offers a 30-year limited warranty on all TruWood products.

TruWood Front Exterior View

Diamond Kote RigidStack

Diamond Kote is a coating for the LP SmartSide Engineered wood siding product, and is considered to be the most popular brand of pre-finished LP SmartSide siding. The Diamond Kote RigidStack product, built on LP SmartSide, is becoming one of the most popular solutions of EWS on the market today.

Diamond Kote Sided House

Explanation of How Diamond Kote RigidStack Siding Works

Summary of Warranty Programs

Here is a summary of each manufacturer’s warranty, with links to see more details on their respective protection programs:

- AZEK: Lifetime Limited Warranty

- Accoya: 50-Year Above Ground; 25-Year At or Below Ground Level

- KWP: 50-Year, Substrate Limited Warranty and 25-Year Finish Limited Warranty

- LP SmartSide: Prorated 50 Year Limited Warranty, Including Hail Damage

- TruWood: 30 Year Limited Warranty

- Diamond Kote: 30-Year No Fade Warranty on Coating used on LP SmartSide Siding

Visual Design Tools & Galleries

- Diamond Kote Dream Home Visualizer

- Diamond Kote Inspiration Photo Gallery

- LP SmartSide Inspiration Photo Gallery

- TruWood Home Visualizer

- TruWood Siding Calculator

Additional Resources

- Understanding the Durability Attributes of Engineered Wood Siding

- Facts and Statistics on Hail

- The Best Siding Option for Hail Resistant

Related Construction & Renovation Articles

- Building Technologies for Disaster Resistant Homes

- Luxury Vinyl Plank Flooring: Friend or Faux?

- 5 Examples of Older Homes Returning Maximum Profit with Renovations

- What is a Turnkey Home in Today’s Market?

- Need Renovation Inspiration? Try These Innovative Design Resources!

- Homebuyer Beware: The Perils of Flipped Homes

- Insights on the Future of Residential Construction from a Futurist

| Purgula is reader-supported. When you click on links to other sites from our website, we may earn affiliate commissions, at no cost to you. If you find our content to be helpful, this is an easy way for you to support our mission. Thanks! Learn more. |