Interior and exterior design of your home is a reflection of your distinctive style and creativity, which can showcase your personality and unique aesthetic. Our homes showcase what is important to us in terms of nature (e.g. plants and trees), furniture (e.g. comfort, style) and overall décor, such as wall art, sculptures, color schemes, and textures.

Interior design elements help us to express who we are, as our own intimate characteristics are on display to signal to guests what we value in our private environment. We search endlessly for the perfect accent chair, sofa or coffee table that suits our style and offers us comfort and delight.

But what options do you have when you cannot find a piece that meets your unique style or functional needs? Additionally, finding the perfect fit in furniture items, in terms of style, height or special physical requirements, is also difficult, especially if the item is not appealing in form and function. Why can’t you find the exact style of sofa or accent chair or objet d’art that meets your exact height, depth or size demands? Fortunately today you can with 3D printing.

3D printing, also known as additive design and manufacturing, can address the need for personalized, on-demand, design décor that is specific to your personal specifications. Additive design is an emerging solution for finding just the right piece of furniture or architectural element that will complement your room or perfect your interior or exterior design style, while meeting your on-demand lifestyle and budget requirements.

Table of Contents

- What is 3D Printing or Additive Design & Manufacturing?

- Use of 3D Printing for Interior Design

- Advantages of 3D Printing Interior Design

- Limitations of 3D Printing Interior Design

- Companies Offering 3D Printing for Interior Design

- Examples of 3D Printed Home Décor Products

- Future Implications for 3D Printing & Homeownership

- 3D Printing for Interior Design Resources

Also see:

- How 3D Printing, Scanning & Models are being used in Restorations

- New Technologies to Restore Time-Ravaged Older & Historic Homes

- Best Try Before You Buy Experiential Retail Programs for the Home

- More Recommended Interior Design Articles

- Related Topics: Interior Design | Home Décor | Home Renovations

What is 3D Printing or Additive Design & Manufacturing?

Using software to design household products is not revolutionary. However, using that same software and a 3D printer to “print” your design into a physical object for everyday use, has become the latest innovation in interior and exterior design to achieve the perfect products for your home or property. Almost any product can be directly fabricated from its 3D model to a special printer to achieve a precise model of the designed item.

Unlike regular manufacturing, 3D printing involves a layered approach, which is “additive” in achieving the optimal product that suits the customer’s individual parameters. Are your legs shorter or longer than average? Use additive design and manufacturing to create furniture, bed frames and other items that address your distinct needs with precision, to create more comfortable items for your home.

The 3D modelling or design phase of additive manufacturing is extremely important and requires special attention before a model can be sent to the printer. Once a composition material has been chosen, printing begins.

Examples of materials that have been used in 3D printing for interior design applications include:

- Plastic Resins

- Cement

- Dirt

- Sand

- Coffee

- Bio-Polyamides, based on Plant Oils

- Salt

- Recycled Rubber

Many other sustainable materials could be used, as well, as long as they have been tested and approved for the final product, such as materials extracted from construction waste streams.

Use of 3D Printing in Interior Design

The term “3D printing” generally conjures up images of industrial design or large commercial projects that lend themselves to endeavors such as auto manufacturing, military and aerospace. True, these industries employ 3D printing technology, and it is the past success in these and other industries that have proven the concept and made it less expensive over time to employ this practice to home furnishings and decor.

Design and manufacturing of custom interior products is not a new concept for consumers. Home furnishings manufacturers and retailer such as Mitchell Gold + Bob Williams and Joybird, made it easy for consumers to design their home decor items to meet their personal preferences.

Although the manufacturing of these designs was and is still performed in the usual method, the concept of bespoke furnishings struck a chord with consumers who want more than mass produced home goods. It is in this area of “personalization” that 3D printing will have a wide impact within interior design and home furnishings.

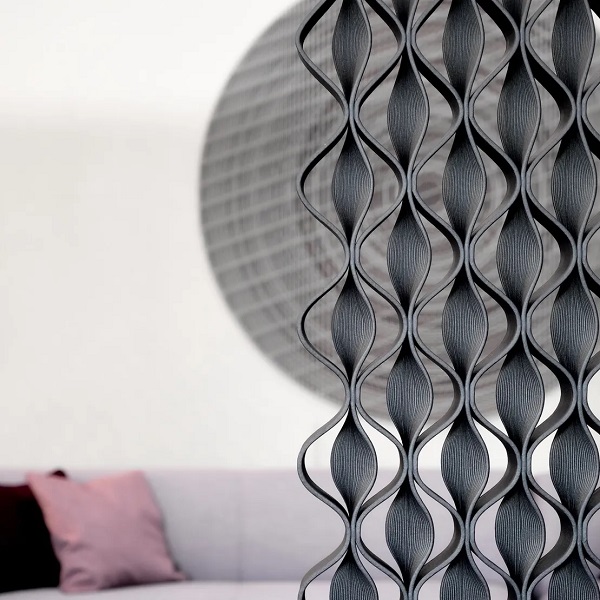

An interior space with Pixel Brick, 3D printed room dividers and screens by Aectual.

Advantages of 3D Printing Interior Design

Admittedly, 3D printing for furnishings and home décor has not hit the mainstream, as it is still emerging as a viable alternative to ready-made goods. However, as consumers begin to discover this approach to getting what they want and need, versus having to adapt to what there is, the industry should grow exponentially.

Additive manufacturing, or 3D printing, is proving to be an extremely advantageous approach to furnishing homes and exteriors for several impressive reasons:

- Flexible Designs & Options

- Variety of Raw Materials

- “Limitless” Use of Shapes, Geometry and Patterns

- Sustainable Production with Minimized Waste

- Sustainable Production with Eco-Friendly Materials

- Strong and Lightweight Parts

- Personalized Solutions

- Cost-Effectiveness

- Convenience

Many of these benefits will expand as innovation and experimentation continues with 3d printing technology and underlying techniques. Keep in mind that the most creative and visionary 3D designers will be pushing the limits of the underlying technology in the coming years.

Limitations of 3D Printing Interior Design

Like most technologies, 3D printing has its own set of limitations that consumers should be aware of upfront to ensure that the end-product will meet their key needs. With time, many of these limitations will be addressed as progress continues within the space.

- Limited Materials

- Limited Textures & Colors

- Restricted Build Size

- Post-Processing

- Part Structure

- Printing Inaccuracies

- Unprintable Models

- Copyright & Counterfeiting Issues

These limitations largely pertain to users of 3D printing technology or persons wishing to have proprietary 3D designs printed. Shoppers of 3D printed products, on the other hand, will be better able to address these types of concerns upfront by inspecting product images and videos, as well as reading details and reviews of specific 3d printed products.

Companies Offering 3D Printing for Interior Design

Aectual

Based in Amsterdam, Netherlands, Aectual creates and sells 3D printed, customizable interior furniture and architectural finishes using recycled materials. With their upcycling approach to design and manufacturing, the company shreds unwanted materials while reprinting objects into new items. This approach is described as a “materials-as-a-service” for the “circular economy”.

Aectuals 3D printed home goods product types include:

- Window Coverings

- Acoustic Panels

- Room Dividers

- Clothes Hangers

- Interior and Exterior Planters

- Flooring

- Furniture Panels

- Outdoor Canopies

Emerging Objects

Berkeley husband and wife, Ronald Rael and Virginia San Fratello, achieved fame with their architectural project known as Prada Marfa in July of 2005, which was created in tandem with Scandinavian artist duo Elmgreen & Dragset.

The minimalist art was a physical structure, modelled after the Italian luxury boutique which is renowned for its high-end shoes and handbags. The art work is remotely located out in the middle of the desert in West Texas.

Rael and San Fratello formed Emerging Objects, to investigate new composite materials with more integrity, rather than the usual plastic that is most associated with 3D printing. The duo has experimented with low cost options such as salt, dirt, coffee, recycled rubber from old tires, and other materials that are available in the construction waste stream.

In their quest to understand how 3D printing works, they have been successful with creating objects of various textures, patterns, strengths and other characteristics, to create homes, furnishings, and cladding to beautify exterior landscapes. Inspired by nature, the couple takes advantage of the shapes and structures to understand function and form to create objects for everyday use.

As an example of this forward thinking, Rael’s lab at UC Berkeley’s College of Environmental Design is investigating the use of milkweed as a building material for acoustic dampening, thermal insulation and oil absorption.

Building a House the Eco-Friendly Way with 3D Printing | KQED Arts

IKEA ThisAbles

IKEA launched its ThisAbles project in 2019 to allow people with special needs and requirements to enjoy the quality of life by creating custom products addressing the gaps of everyday furniture and furnishings.

Joining forces with the Israeli non-profit organizations Milbat and Access Israel, IKEA has a vision to create a revolutionary line of products that can be customized and 3D printed for customers on demand. The ThisAbles website has a button inviting anyone with a need for a product to connect with the company to help further the product lines and development of new features for existing consumables.

IKEA ThisAbles Case Study by McCann Tel Aviv

Nervous System

Generative design firm Nervous System seeks inspiration from the beauty of nature. The digital designs of its Hyphae Lamps, for example, are derived from the veins of leaves, with its finished product fabricated using 3D printing. Each lamp is unique and comes with eco-friendly, efficient LED bulbs to create ethereal, dramatic shadows based on the designs and intricate patterns of their sculptures. In addition to lamps, the company also makes housewares, puzzles, jewelry, and gift boxes.

Roche Bobois

Perhaps the strongest validation toward the emerging use of 3D design and printing for home interiors is the entrance of luxury brand, Roche Bobois, as they introduced their 3D printed, concrete, and fully customizable Corail dining table in 2021.

Additive manufacturing allows upscale brands, to offer their customers their own designs to accentuate their interior and exteriors, while reducing the manufacturing and delivery times of the finished product.

Also see:

Wooj

Wooj is a recently founded design firm out of Brooklyn, New York that makes sustainable, 3D printed home goods from eco-friendly materials, such as recycled corn PLA. Their approach is to use a combination of robotics and craft manufacturing techniques. Their most popular product is the Wavy Lamp, inspired by the look-and-feel of Noguchi lamps.

Is 3D Printing The Future of Furniture?

Examples of 3D Printed Home Décor Products

- Lighting Features & Effects

- Acoustic Panels

- Furniture

- Pottery, Vases & Planters

- Room Dividers

- DIY Coffee Table

Lighting Features & Effects

Black Hyphae Lamp by Nervous System

3D Printed Puzzle Lamp by Nervous System

Acoustic Panels

Acoustic Panel Weave by Aectual

Furniture

Corail Dining Table by Roche Bobois

“Meshmixed Modern” using 3D Printed Support Material by Emerging Objects

Seat Slug is a Biomorphic Interpretation of a bench by Emerging Objects

Pottery, Vases & Planters

Planter Tile in Cement by Emerging Objects

Outdoor Mussel Planter by Aectual

Also see:

Room Dividers

3D Printed Room Divider with Gradient Curve by Aectual

DIY Coffee Table

Here is a fun example of a DIY 3D printed coffee table using a Creality CR-30 3D printer. The end product proves to be strong enough for its talented creator, Scott Yu-Jan, to stand on. This video also illustrates how creative types will envision uses for 3D printers likely unimagined by early 3D printing technologists.

Making Furniture with a 3D Printer?! Featuring the Creality CR-30 3D Printer

Future Implications for 3D Printing & Homeownership

Within the broad scope of housing, we expect that 3D printing will have an enormous positive impact for many years to come. Here are a few important scenarios of how we see 3D printing influencing residential living, homeownership, and shopping for the home:

- Home Maintenance

- Aging in Place & Assistive Technology

- Integration with Digital Twins

- 3D Printed Houses

- Hyper-Efficient 3D Printed Sourcing & Shopping

- Restorations

Home Maintenance

In terms of home maintenance and appliance repairs, we expect to see consumer-facing manufacturers to follow the lead of advanced manufacturing practices by leveraging components and parts that can be created using 3D printing.

This approach will be attractive to consumers as, in theory, products and home systems can have extended lifespans, as a larger selection of replacement parts can be virtually stored and created on-demand, as needed. More discerning consumers will start asking customer support reps if a given replacement part can be 3D printed to expedite “delivery”, as well as to reduce costs.

Aging in Place & Assistive Technology

Since the market for “Aging in Place” residents will continue to grow for many years, 3D printed solutions will help the industry rapidly adapt to new effective applications, as well as to provide critical personalization (e.g. size, strength, unique uses, etc.), affordability and rapid implementation for changing personal circumstances.

IKEA’s ThisAbles initiative will surely inspire further, wide-ranging and affordable innovation that will emerge in assistive technology solutions, as well.

Also see:

Integration with Digital Twins

3D printed products and components will help further push the adoption of digital twins for the home, as they already will be adhering to industry standards for software applications and data definitions. Digital Twins will also make home maintenance tasks and repairs more convenient with the ability to order 3D printed replacement parts within future apps.

3D Printed Houses

Though we are still in the early days of 3D printed housing, we envision seeing 3D printing being used for creating smaller components of homes by builders taking hybrid approaches to construction (e.g. more prefab elements, including 3D printed materials). This approach will help introduce more affordable customization and long-term flexibility, while improving the aesthetics of contemporary 3D printed homes.

Hyper-Efficient 3D Printed Sourcing & Shopping

3D printed products will grow and maintain close affinity with the following consumer benefits:

- Easy personalization

- Fast fulfillment times

- Lower costs

- More convenient “shipping” and delivery options

How consumers shop for their homes will evolve quickly, as new 3D offerings expand and shoppers become more aware of 3D printed marketplaces. For example, shoppers of 3D products will start to break up their research into the following stages:

- Worldwide 3D models and designs

- Best 3D print materials for a given application, product type or aesthetic

- 3D Printing Facilities & Capabilities: at-home, local, regional, national or international that is best suited to print desired end-products or materials

- Balancing shipping and delivery logistics and tradeoffs of sourcing 3D printing at-home, locally, regionally, nationally, or internationally

Restorations

To learn more about how 3D printing is being used for restoration projects, see our article:

3D Printing for Interior Design Resources

- Aectual 3D Printed Interior Décor Shop

- Emerging Objects Portfolio

- Potterware

- 3D Potter

- Lutum 3D Clay Printer

More Recommended Interior Design Articles

- 3 Interior Design Features of UK Homes We Love in the US

- Top 5 Color Schemes for Your Living Room

- Can the Doors You Choose Make a Difference to Your Interior Design?

- Why You Should Apply Cinematically Inspired Design to Your Home

- How to Apply Transformable Interior Design to Your Home

- Need Renovation Inspiration? Try These Innovative Design Resources!

- A Before vs. Virtual vs. Real Life Renovation Case Study

- Ornamental Design: Inspiration from Lenna Tyler Kast’s Villa Bel-Ami

| Purgula is reader-supported. When you click on links to other sites from our website, we may earn affiliate commissions, at no cost to you. If you find our content to be helpful, this is an easy way for you to support our mission. Thanks! Learn more. |